Polysulphide Sealant

Polysulphide Sealant Specification

- Packaging Size

- 1 kg, 5 kg, 10 kg, 25 kg

- Holding Power

- High

- Glue thickness

- 2-5 mm

- Adhesive Type

- Elastomeric Sealant

- Material

- Polysulphide Rubber

- Shelf Life

- 12 months

- Surface Of Application

- Concrete, Metal, Glass

- Storage Temperature

- 5C - 30C

- Tensile Strength

- 1.5 MPa

- Types Of Chemical

- Polymeric Sealant

- Form

- Paste

- Features

- Excellent UV resistance, High flexibility, Chemical resistance, Waterproof

- Hardness

- Shore A 25 5

- CAS No

- 68425-34-1

- Other Names

- Polysulfide Sealant, Thiokol

- Usage

- Construction

- Grade

- Standard

- Purity

- 98%

- Application

- Industrial

- Color

- Grey

- Physical State

- Liquid

- Curing Time

- 24-48 hours

- Service Temperature Range

- -25°C to +80°C

- Skin Formation Time

- 2-4 hours

- Application Tools

- Spatula, Caulking Gun

- Density

- 1.5 ± 0.1 g/cm³

- Elongation at Break

- > 300%

- Resistance

- Resistant to fuels, oils, solvents

- Pot Life

- 60-90 minutes

- VOC Content

- Low

- Chemical Composition

- Polysulfide polymer blend

Polysulphide Sealant Trade Information

- Minimum Order Quantity

- 100kg Packs

- FOB Port

- Ahmedabad

- Payment Terms

- Cheque

- Supply Ability

- 100 Packs Per Day

- Delivery Time

- 15 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- 4 kg (Component A = 3.68 Kg, Component B = 0.32 kg )

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- On request

About Polysulphide Sealant

Polysulphide Sealant is intended to be used for floor expansion joints, precast concrete, bridge deck joints, and car parking areas. It is completely suitable for both horizontal & vertical sealing applications with complete reliability. This sealant is easy to use and is considered to be economical as compared to other brands. It shows excellent weather resistance and is ideal for both high & low rise buildings. Polysulphide Sealant possesses good elastic properties and is said to be best where permanent flexible sealing is required.

Features:

- Assures excellent adhesion with most substrates

- Good resistance to most chemicals

- Has non-sagging nature

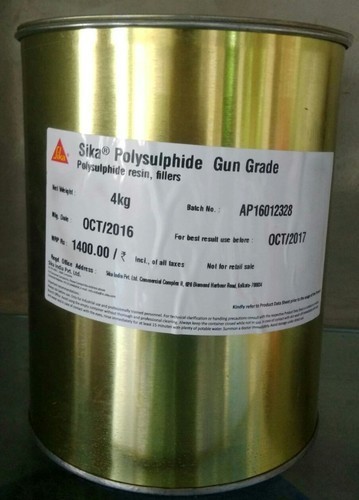

Sika Polysulphide is a cross linking polysulphide based elastic sealant for vertical and horizontal expansion joints.

Technical details

|

Chemical Base |

Cross linking polysulphide |

|

Packaging Size |

4 kg (Component A = 3.68 kg, Component B = 0.32 kg ) |

|

Brand |

Sika |

|

Shelf Life |

12 months |

|

Form |

Paste |

|

Color |

Grey |

|

Curing Time |

24 hours |

|

Pot Life |

2 hours |

|

Density |

1.62 kg/L |

Advanced Performance and Durability

This polysulphide sealant combines high flexibility with robust chemical resistance, tolerating harsh industrial environments and extreme temperatures. Its impressive elongation at break enhances protection and accommodates structural movement efficiently.

Efficient Application and Fast Skin Formation

Designed with a 60-90 minute pot life and a skin formation time of 2-4 hours, the sealant is convenient for industrial projects. It ensures sufficient working time for precise application, yet begins forming a protective layer promptly, streamlining project schedules.

Safe and Sustainable Choice

With a low VOC formulation and 98% purity, this sealant supports healthier working conditions and environmental responsibility. It is suitable for use in construction sites across India, aligning with modern sustainability standards.

FAQs of Polysulphide Sealant:

Q: How should Polysulphide Sealant be applied in construction projects?

A: Polysulphide Sealant should be applied using a spatula or caulking gun. The surface must be clean and dry before application to ensure proper adhesion and optimal sealing performance.Q: What benefits does the high elongation at break offer to users?

A: With an elongation at break greater than 300%, this sealant accommodates significant structural movement, preventing cracks and leaks even under dynamic loading conditions.Q: When is the sealant fully cured and ready for service exposure?

A: The sealant achieves full cure within 24-48 hours, depending on ambient temperature and humidity levels. Once cured, it withstands a service temperature range between -25C and +80C.Q: Where is Polysulphide Sealant most commonly used in India?

A: It is widely used in industrial and construction sectors throughout India, especially for joints and gaps requiring durable, chemical-resistant sealing in structures, tanks, pipelines, and concrete surfaces.Q: What is the recommended process for achieving optimal results?

A: For best results, apply the sealant within its 60-90 minute pot life and ensure a skin formation time of 2-4 hours. Regular inspections during application aid in achieving consistent coverage and bonding.Q: How does its chemical composition enhance performance in challenging environments?

A: Featuring a blend of polysulfide polymers, the sealant resists the detrimental effects of fuels, oils, and solvents, making it suitable for demanding industrial and construction applications.Q: What are the key usage and environmental benefits of this sealant?

A: Its low VOC content and high purity contribute to a safer workspace and minimal environmental impact, ensuring compliance with current industry standards for sustainable operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

VIHAN TECHNO SOLUTIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |