High Strength Micro-Concrete

High Strength Micro-Concrete Specification

- Physical Form

- Powder

- Usage

- Construction

- Color

- Gray

- Appearance

- Powder

- Application

- Industrial

High Strength Micro-Concrete Trade Information

- Minimum Order Quantity

- 100 kg Packs

- FOB Port

- Ahmedabad

- Payment Terms

- Cheque

- Supply Ability

- 100 Packs Per Day

- Delivery Time

- 15 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- 30 kg bags.

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- On request

About High Strength Micro-Concrete

High Strength Micro-Concrete is most commonly utilized for damage repairing purpose of concrete structures including pier & pile caps. It possesses the good anti-wash property and high bonding strength. This micro-concrete is highly durable in nature and is known to be chloride-free. It appears as grey colored powder and is also suitable for grouting of large gaps. High Strength Micro-Concrete offered by us is considered perfect for underwater repairs with great reliability and bond strength.

Features:

- Shows low porosity

- Long shelf life

- Non-shrink nature

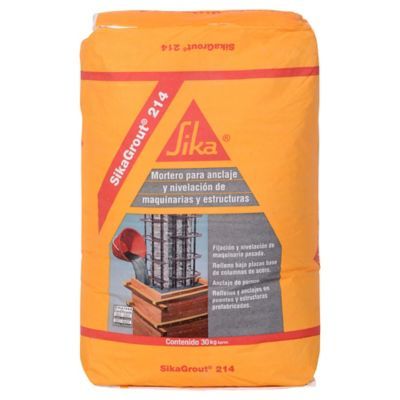

SikaRep Microcrete -4 is factory designed pourable, non shrink, repair concrete with selected cement, aggregate and other chemicals. Recommended water and coarse aggregate to be added at site as per requirement.

Technical details

|

Bulk Density |

1.2 kg/L (of fresh mortar) |

|

Packaging Type |

Bag |

|

Usage/Application |

Column, Beam, Slab etc |

|

Packaging Size |

30 kg |

|

Color |

Gray |

|

Brand |

Sika |

|

Standards |

ASTM C1107 |

|

Shelf Life |

6 months |

|

Mixing Time |

5 minutes max |

|

Form |

Powder |

Superior Bonding and Strength

Our High Strength Micro-Concrete offers exceptional bonding with existing structures and rapidly achieves high compressive strength. This ensures minimal downtime and enhanced safety during critical industrial repairs or restorations.

Easy and Efficient Application

Supplied as a ready-to-mix dry powder, our micro-concrete requires only the addition of water for immediate use. This streamlined process cuts labor time, simplifies handling on-site, and ensures consistent results across various industrial applications.

FAQs of High Strength Micro-Concrete:

Q: How should High Strength Micro-Concrete be applied in industrial construction projects?

A: High Strength Micro-Concrete is typically mixed with clean water to produce a pourable or flowable consistency. The prepared mixture is then poured or pumped directly into the repair area, ensuring good coverage and compaction, especially for inaccessible or congested sites.Q: What are the main benefits of using High Strength Micro-Concrete for industrial purposes?

A: The key benefits include rapid strength gain, superior adhesion to old concrete, non-shrinkage, and resistance to harsh environments. These characteristics make it ideal for repairs and structural rehabilitation in heavy-load industrial settings.Q: When is High Strength Micro-Concrete most effectively utilized on a construction site?

A: This micro-concrete is best used when quick repair and high early strength are critical, such as in structural retrofitting, machine base grouting, and column or beam restoration, minimizing operational disruptions.Q: Where can High Strength Micro-Concrete be sourced in India?

A: It is available through specialized service providers, suppliers, and traders throughout India who focus on construction materials for industrial and infrastructure projects. We offer reliable supply and support nationwide.Q: What is the typical process for using this powdered micro-concrete on-site?

A: The product should be mixed thoroughly with the recommended water ratio until a uniform, lump-free slurry forms. Once mixed, it must be applied promptly to prepared and pre-wetted surfaces to achieve optimal strength and bonding.Q: How does the gray color of this micro-concrete benefit industrial aesthetics and repairs?

A: The gray shade closely matches traditional concrete, providing a visually cohesive finish in repair areas and reducing the need for additional surface treatments or color corrections.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

VIHAN TECHNO SOLUTIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |